It is a top of the page.

- Home

- Sustainability

- Society

- Food Safety and Security

Food Safety and Security

Basic Policy

Duskin prioritizes the safety of the food we provide to customers. And to make sure we do not impose any negative impacts upon our customers, we set quality standards, ensure safety, and deliver peace of mind for all food products from the development stage to supply and even up to consumption by the customer.

Food Safety Council

All product development and specification changing has safety checked through the process of holding the "Food Safety Council" composed of participants from third-party departments, such as the Food Product Safety Manager, the Product Development Supervising Division, and the Quality Assurance Supervising Division.

Based on legal regulations and our own company standards, we monitor the process of checking on the raw materials we use and the place of origin, legal compliance for additives, allergen information, appropriateness of the foreign matter removal process, the status of management for residual pesticides and antibiotics, results of inspections on the preservation of products and raw materials, status of management for consigned production plants, distributors, and storage providers of products and raw materials, and handling procedures at sales branches, and check safety at every stage.

Moving forward, with priority given to strict checks ensuring raw materials and products are being used how they are supposed to be used, we will continue to follow up to promote deepened comprehensive understanding regarding safety among development workers.

Inspecting distributors and storage providers

In order to maintain the quality of products and raw materials, we implement investigations that involve 300 checkpoints for new transactions on the operation conditions of distribution branches that store raw materials and deliver them to sales branches, including the storage conditions, temperature control, and deadline management at these distribution branches.

In addition, the Purchasing and Distribution Supervisor at the Mister Donut business headquarters conducts periodic inspections.

Hygiene management at sales branches

At Food Business shops including Mister Donut, thorough hygiene management is employed on a daily basis. For example, when employees enter the shop, they perform physical checks including everything from health status to fingertip hygiene and incorporate hygiene control items in each work process, thus conducting thorough hygiene management.

Also, we have an external inspection body perform periodic spot hygiene inspections without prior notification four times per year. In addition to conducting inspections with over 100 items checking hygiene management status and bacteriological inspections of donuts and drinks via samples, we also strive to strengthen the prevention of contamination from bringing items into the shop. We maintain comprehensive hygiene management conditions by receiving evaluations and guidance for improvement from the specialist viewpoint of external inspection bodies.

Introducing hygiene management that incorporates HACCP ideas

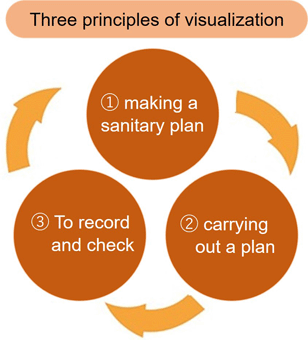

To prevent food poisoning and contamination, hygiene management that incorporates HACCP* ideas has at its foundation the process of creating visual representations of hygiene actions by thoroughly implementing and recording pre-planned hygiene management cautionary points.

Recording actions that have been implemented thoroughly makes it possible to discover various signs of trouble before it occurs and provides an opportunity to reassess maintenance, repair, etc., ultimately leading to the prevention of grave food product accidents.

- *HACCP stands for Hazard Analysis and Critical Control Point. It is a hygiene management method to ensure product safety by controlling important processes to reduce the risk of harm within the process extending from receiving raw materials to finishing, storing, and shipping (serving), based on a prior understanding of the risk of harm such as foodborne bacterial and foreign object contamination.

Information supply concerning food safety and security

Providing nutritional information (better nutritional information access)

At Mister Donut, we disclose product nutritional information (calories, protein, fat, carbohydrates, and salt equivalent) in accordance with established labeling standards. We update the information as needed for circumstances such as new product releases and product improvement.

At the shop, staff members print out and provide nutritional information to customers on request. Also, nutritional information for each product is viewable on the official Mister Donut website.

In addition, the calorie amount in each product is shown on the price card at the shop.

Providing allergy information

Amid broad societal recognition of allergy-related needs surrounding food products, Mister Donut strives to make allergy information available to the many customers who need it. At shops, product price cards are labeled to indicate any of the common allergen ingredients the products contain. Upon customer request, staff members print out and provide a list displaying information on any ingredients that are equivalent to common allergens.

Also, allergy information about each product can be viewed on the official Mister Donut website.

Mister Donut nutritional information and allergy information (www.misterdonut.jp)

- Note: The English version is at the bottom of the linked page.

Information on the origin of primary ingredients

- For any inquiries about the origin of primary ingredients of Mister Donut products, please contact:

- Mister Donut Customer Center

- Telephone: 0120-112-020 (only available in Japan)

- Office hours: 9:00 am to 5:00 pm, except for Sunday

Preventing unwanted second-hand smoke

In the Mister Donut business deployed by our Food Group, we have implemented actions such as all-day no-smoking, no-smoking time slots, and non-smoking areas at each shop.

Meanwhile, the Revised Health Promotion Act, which came into full force in April 2020, calls for enhanced measures concerning "unwanted second-hand smoke". Therein, all shops including those that had already installed smoking areas and ventilated smoking areas implemented either "the complete prohibition of smoking" or "the installment no-seating smoking booths that do not allow eating or drinking".

And to make our shops more pleasant and safe for customers with children as well, we also continually aim for a shop environment that considers the health condition of employees working there.

Participating in initiatives of related industries

In addition to participating in committees as a member company of the Japan Foodservice Association*, an industry group overseeing the entire Japanese food-service industry, we also cooperate with policy recommendations for the food-service industry and survey activities including food-service industry market trend surveys.

We strive to refer to and comply with the guidelines formulated by the Association.

- *Japan Foodservice Association (JF) was established in 1974 with certification from the Ministry of Agriculture, Forestry and Fisheries to contribute to the growth of the Japanese food-service industry and the creation of a rich food culture. The number of affiliated companies including both regular and supporting members is over 800 companies, making this the largest organization related to the food-service industry.

Initiative examples

Early adoption of low trans fat oil

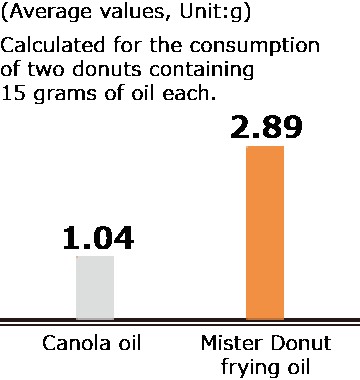

Consuming large amounts of trans fat is said to increase the risk of coronary heart diseases due to a higher bloodstream concentration of LDL cholesterol (low-density lipoprotein, or "bad" cholesterol) and a lower bloodstream concentration of HDL cholesterol (high-density lipoprotein, or "good" cholesterol). *1 The average trans fat intake quantity in Japan is lower than in other countries, and no specific standards have been established. *2 However, Mister Donut dove into the issue of trans fat from an early stage, and in December of 2007 started using oil with significantly lowered trans fat amounts at all shops. Furthermore, research has also shown that Mister Donut frying oil has the additional characteristic of being difficult to absorb into the body.

As another method of reducing trans fat, in addition to oil, we have also deployed repeated research and development for the raw materials of "mix powder" and "coating material", and keep the average trans fat in all of our donut and pie items to approximately 0.25g. *3 In our research and development, we focused on maintaining the flavor, texture, and aroma of Mister Donut traditionally loved by our customers.

- *1 : The disease risk is based on the 2003 report of a joint expert meeting from the World Health Organization (WHO) and the Food and Agriculture Organization of the United Nations (FAO).

- *2 : In Japan, according to data announced in 2008 (estimated from the amount produced), trans fat intake quantity is an average of 1.32g per day and the percentage of trans fat to total intake energy is approximately 0.6%, which clears the WHO and FAO recommendation of "less than 1% of total intake energy".

- *3 : "Approximately 0.25g" is the average value for all items we provide as of April 1, 2016 (according to research by Mister Donut). Numerical values are calculations based on component ratios. Each product is made by hand at the shop, so some small divergence from numerical values may occur.