It is a top of the page.

- Home

- Sustainability

- Environment

- Resource Recycling

- Efforts for Waste Reduction

Efforts for Waste Reduction

Basic Policy

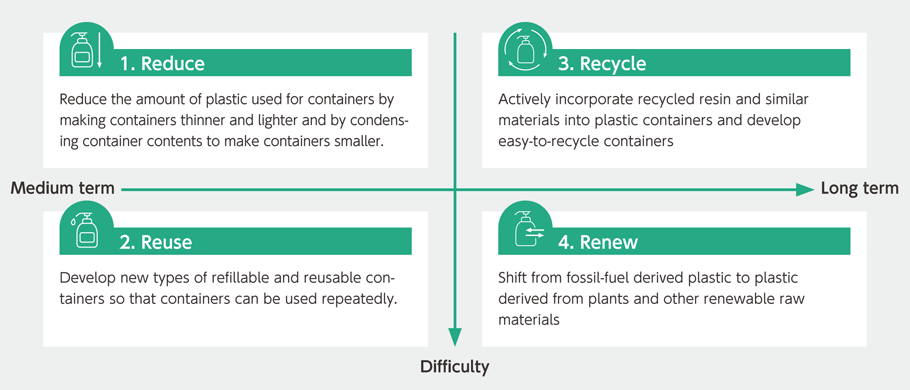

Duskin recognizes that plastic has a major impact on our lifestyles and the natural environment, including its contribution to the marine refuse problem. As such, we strive for the effective use of resources and the reduction of environmental burden throughout the entire life cycle of packaging plastic. Additionally, in the business areas of the Direct Selling Group and Food Group, we strive for the reduction and reusing (recycling) of waste generated in their various business activities. And, to contribute to the actualization of a sustainable society, we promote the following efforts.

■Our joint investment efforts

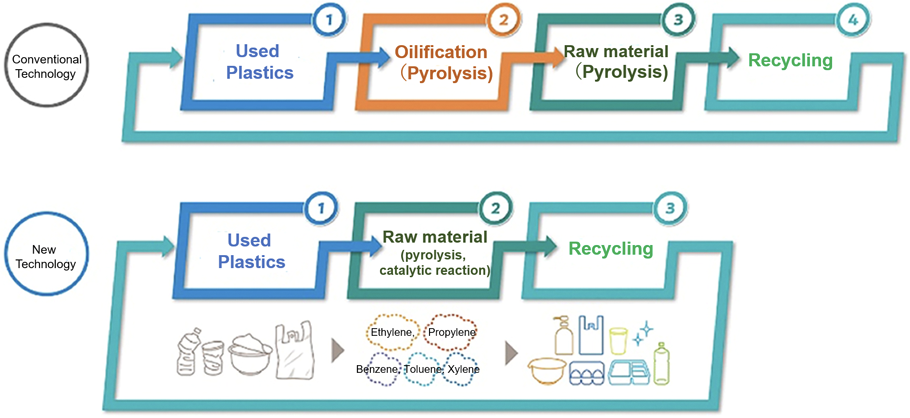

Duskin capital sharing partner R Plus Japan Co., Ltd. has teamed with American biochemical venture company Anellotech Inc. to develop recycling technologies for used plastics that are less environmentally burdensome and more efficient. To contribute to resolving plastic issues shared worldwide, in addition to sorting and processing collected plastics, monomer manufacturing, polymer manufacturing, and plastic container manufacturing, we have also formed industry-transcending links to companies including trading firms and food and beverage producers in our mission to actualize practical application by 2027.

■Used plastic recycling technology

Currently in Japan, most plastics other than plastic bottles are disposed of by burning *1. This current technology development is a chemical recycling *2 technology that returns plastic bottles and other general plastics to direct raw materials (benzene, toluene, xylene, ethylene, propylene, etc.). If this technology is successful, it will allow plastics to be converted through less processes than chemical recycling via the traditional oilification method. It is expected to lead to the curbing of CO2 emissions and energy requirements. We believe this will lead the way to more efficient reuse of used plastics.

- *1.Includes thermal recovery (heat utilization), in which heat generated during incineration is recovered and utilized for power generation and heat supply.

- *2.Recycling used resources after compositional transformation via chemical reaction instead of reusing them as is.

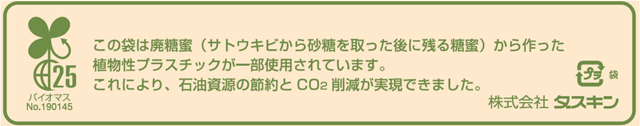

25% environmentally friendly biomass bags

Since July 1, 2020, paying for plastic shopping bags at the register became mandatory nationwide. However, because bags that have a biomass logo from being at least 25% biomass (vegetative matter) are not subject to payment, we are able to offer free-of-charge bags for products like mops for residential use.

Moving forward, by introducing environmentally friendly materials into products and packaging currently using petroleum-derived plastic material, we will contribute to CO2 reduction and preserving the global environment.

Plastic product reduction efforts

Since 1974, Mister Donut has used ceramic and glass tableware rather than disposable paper containers.

Note: At shopping mall food courts, however, paper cups are used, since the use of ceramic cups and dishes or glasses is restricted there

Also, in place of plastic straws, we provide biomass straws *1 that curb actual CO2 emissions and give a more pleasant drinking experience than paper straws.

- *1 We use resin straws partly made from biomass material.

Waste reduction in the Direct Selling Group

Our Production & Logistics facilities reduce waste generation with effective use and reuse of resources. Mops that are no longer useable as products are reused as industrial mops.

Recyclable items other than mops and mats are collected by our offices and sent to plants. The items are then sent to recyclers and nearly 100% are recycled.

| Waste item | Recycling method | Recycled amount | ||||

|---|---|---|---|---|---|---|

| FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | ||

| Dust on rented products (cleaned and recycled into wastewater sludge) (t) |

Cement raw material at cement companies | 10,159 | 9,678 | 9,163 | 8,560 | 8,841 |

| Products that failed inspection (mops & mats) (t) | Cement raw fuel at cement companies | 2,634 | 2,809 | 2,917 | 2,774 | 2,602 |

Waste reduction in the Food Group

Donut waste reduction and recycling as animal feed

Mister Donut strives to provide a variety of donuts for customers to choose, even just before store closing time. Mister Donut therefore makes continued efforts to recycle any unsold donuts.

Shops in the Tohoku, Kanto, Tokai, Kinki, Chugoku, Shikoku, and Kyushu areas take unsold donuts to animal feed processing plants and recycle them as animal feed.

Mister Donut reviews production schedules and executes tight controls by using a checklist to reduce donut disposal.

| FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |

|---|---|---|---|---|---|

| Quantity of food waste (t) | 4,305 | 4,735 | 4,521 | 5,311 | 5,302 |

| Quantity curbed (t) | 2,373 | 3,264 | 4,509 | 5,369 | 6,379 |

| Implementation rate for recycling etc. (%) | 55.0 | 59.3 | 69.1 | 69.4 | 73.5 |

| FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |

|---|---|---|---|---|---|

| Compared to FY 2000 (%) | 41.6 | 35.7 | 50.1 | 52.0 | 51.5 |

Recycling and reusing donut cooking oil

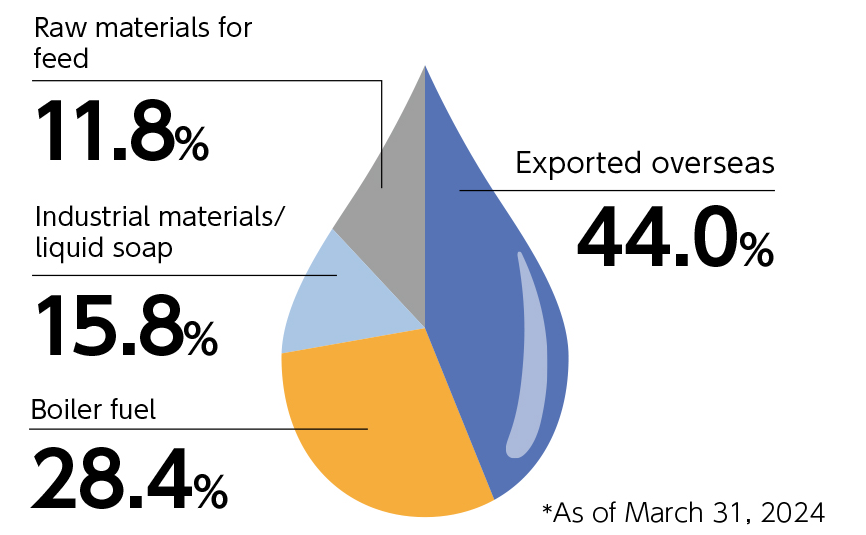

Old donut cooking oil is recycled mainly as industrial raw material and liquid detergent used at the shop.

In some regions, the oil is also used as boiler fuel in Duskin plants that clean and recycle mats and mops.

Also, by utilizing it for animal feed and biofuel, we actualize a 100% oil recycling rate.

Mister Donut

Eco-frien-DOUGH-ly Activities

As a company responsible for handling precious earth resources, Mister Donut has continually contributed to environmental friendliness. Commemorating our 50th year since inception, we are even more devoted to environmentally friendly efforts.