It is a top of the page.

- Home

- Sustainability

- Environment

- Water Resource Conservation and Pollution Prevention

Water Resource Conservation and Pollution Prevention

Basic Policy

Water shortages are becoming more serious on a global scale due to climate change, deforestation, and population and economic growth in emerging and developing countries. For companies, water scarcity is also a risk that could impact even business survival, and reducing and reusing water is an important issue.

Japan has not reached chronic water scarcity as a nation, but the effects of water issues like scarcity and pollution are not unknown to the Duskin Group.

Based on the awareness of these issues, we have a phrase that has been passed down since our inception as a basic principle for water resource conservation: "Resources we have borrowed from nature must be returned to their natural state and given back to nature." Moving forward, we will maintain that same stance in promoting the effective use of water resources and conservation activities for water quality.

Water management (water usage quantity / leakage reduction targets)

We create and maintain water management plans for all 45 of our franchised, company-owned and affiliated plants, and set and manage standard water values (targets lower than previous FY usage quantity) for each period based on the performance of each plant.

Initiatives at production and logistics facilities

Legal compliance

Concerning water discharged from our production and logistics facilities, the Duskin internal company standard is to make sure it is 80% or lower (70% or lower for toxic substances like heavy metals) than the regulatory values in the Water Pollution Prevention Act and Sewerage Act.

Twice a month we run our own independent internal surveys, and if the results exceed our own internal company standards, the data is submitted from the plant to the headquarters where a response plan is considered.

Water risks

We believe that for the operation and continuation of Duskin Group business activities, it is important to be able to use a sufficient amount of water resources at all of our production and logistics facilities and throughout the entire value chain.

Possible risks related to water are thought to include physical, regulatory, and reputational risks, for which concern is increasing worldwide.

Concerning risks considered to have the potential to impact business at our production and logistics facilities and Research & Development facilities, we strive to assess the potential impact to business based on physical, regulatory, and reputational risks such as water scarcity, water quality degradation, drainage wastewater quality and quantity regulations, and the efficient usage of water. We then conduct analysis based on the results of that assessment.

| Risk cause | Major impact |

|---|---|

| Water scarcity | Decline in research and production activity when water supply is suspended or restricted |

| Water quality degradation | Increase in water purification costs |

| Flooding, high tides, and torrential rain |

Flooding of facilities, etc. from river overflow |

| Full mandating of water efficiency, recycling, etc. |

Cost increases for facility investments, etc., from full mandating of water reusing |

| Strengthening of regulations for drainage wastewater quality and quantity |

|

| Changes in water supply seasonally and over years |

Impact from changes to stable operation |

| Water price hikes | Increases in operation costs from water price increases |

| Regional society | Responses to land sinking, etc. due to pumping up underground water |

Conducting water risk surveys

Using the World Resources Institute (WRI) Aqueduct, we evaluate water risks concerning all 45 of our franchised, company-owned and affiliated plants.

Our production and logistics facilities span the entire nation, but none of them are standing in areas classified at Medium-high or higher via the evaluation conducted with the WRI Aqueduct, and our evaluation also found that none of them are exposed to water stress.

We feel there are no major concerns regarding water usage, wastewater drainage, etc. at present. However, we will still periodically monitor water intake quantity, wastewater drainage quantity, and risk level for each production and logistics facility.

| Comprehensive water risk |

Locations | Percent |

|---|---|---|

| 0-1 Low | 13 | 28.9% |

| 1-2 Low-Medium | 32 | 71.1% |

| 2-3 Medium-high | 0 | — |

| 3-4 High | 0 | — |

| 4-5 Extremely high | 0 | — |

| Total | 45 | 100.0% |

Water intake quantity reduction and wastewater drainage management

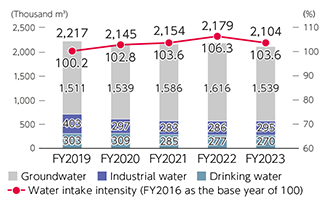

Water intake

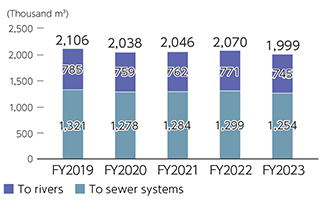

Wastewater

Production and logistics facilities use a great deal of water in the mop and mat cleaning process. Duskin's such facilities strive to manage and reduce water intake based on the standard amount used during processing.

Additionally, dirty used water is treated in the plants under the supervision of an in-house wastewater treatment licensed staff member and discharged after meeting our own discharge standards, which are stricter than legal standards.

Also, we continually receive third-party guarantees concerning water intake quantity.

Independent third-party assurance report [PDF: 522KB]

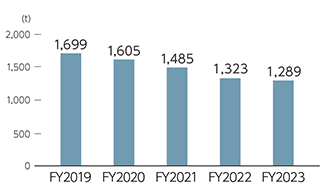

Detergent usage quantity reductions

The detergent used at our production and logistics facilities is essential in order to provide clean mops and mats to our customers. However, considering its impact on water, we strive to minimize how much we use, and use it efficiently.

Duskin is engaged in reducing the amount of detergent used, with efforts such as increasing detergent dissolving performance by implementing water softening treatment on cleaning water.

Monitoring discharged water

Concerning water discharged from our production and logistics facilities, our internal company standard is to make sure it is 80% or lower (70% or lower for toxic substances like heavy metals) than the regulatory values in the Water Pollution Prevention Act and Sewerage Act.

Twice a month we run our own independent surveys, and if the results exceed our own internal company standards, the data is submitted from the plant to the headquarters where a response plan is considered.

Chemical substance control

Basic Policy

Concerning the usage of chemical substances for newly introduced products, rental product processing materials, service processing agents, etc., we define control and operation standards in "Chemical Substance Management Guidelines" that enforce compliance with usage restrictions, control standards, etc. from law and industry conventions.

We review the "Chemical Substance Management Guidelines" and "Management of Chemical Substance List" once per year.

Compliance with environmental laws and regulations

At the Duskin Group, we are aware of the applicable laws and regulations and periodically check our compliance status. For ISO-certified operations, we also confirm compliance status with environmental laws and regulations during environmental audits.

| FY 2023 | |

|---|---|

| Fines for violating environmental laws or regulations | 0 yen |

| Legal violations concerning water intake / wastewater drainage | 0: No instances of legal violations |

Taking away dirty water after servicing

and take dirty water away.

We take away dirty water that is generated during servicing, like dirtied cleaning water from air conditioner cleaning and dirty soaking water from stovetop hood cleaning. We then perform neutralizing treatment on the water, and dispose of it appropriately.

Our pest extermination system minimizes chemical usage

In our Terminix pest extermination service, we prioritize inspections and preventative control, and promote the adoption of a system that minimizes the use of actual chemicals. In termite and cockroach extermination, we use the "bait method" that employs special extermination bait infused with small amounts of chemicals.