It is a top of the page.

- Home

- Sustainability

- Environment

- Climate Change Response

- CO2 Emission Reduction Efforts

CO2 Emission Reduction Efforts

Basic Policy

As impacts arising from climate change such as abnormal weather gradually grow in severity, climate change response has become a worldwide issue. Duskin promotes environmental management, and in order to contribute to the creation of a sustainable society, we actively contribute to efforts to actualize a low-carbon society and resolve issues as a sustainable company.

Indexes and targets

| Materiality | Core efforts | KPIs | FY 2024 performance | |

|---|---|---|---|---|

| Climate change response |

|

2030 targets | Duskin Group locations: Light commercial vehicles EV ratio 30% | — |

| CO2 emissions at Duskin Group locations: 46% reduction (Compared to March 2014) |

26.9% (Compared to March 2014) |

|||

| Renewable energy usage rate: 50% | 19.0% | |||

CO2 emission reduction efforts

Energy conservation actions at production and logistics facilities

Our production and logistics facilities that wash and recycle used mops are reducing CO2 emissions. In addition to introducing energy-conserving facilities, we engage in energy loss reduction and energy saving through the periodic maintenance of existing facilities and facility operation streamlining.

(Osaka Central Plant)

Energy reduction targets

For each period, we set and manage standard usage volumes (target values) based on performance for each production site.

Installing solar power generation systems

At company-owned locations, we strive to reduce the usage of energy from fossil fuels by installing solar power generation facilities and using renewable energy.

The Duskin School training center employs solar power generation panels on part of the glass walling, and started generating energy in 2010. In 2013, we introduced a solar power generation system at our Osaka Central Plant, installed a module with approximately 350 panels, and are generating energy on the scale of a 100kW maximum output.

Moreover, we have also begun introducing solar power generation at company-owned locations belonging to Direct Selling Group. This allows us to do more than strive for the effective use of renewable energy, but to also use company-owned locations as regional response centers during disaster blackouts. We will continue to introduce these systems moving forward.

The approx. 350-panel module installed atop the Osaka Central Plant roof

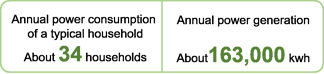

- *The total power consumption per one household is 4,734kWh/yr

(Source: "Report on Survey into Consumed Power at Standby" by The Energy Conservation Center, Japan)

- *The total power consumption per one household is 4,734kWh/yr

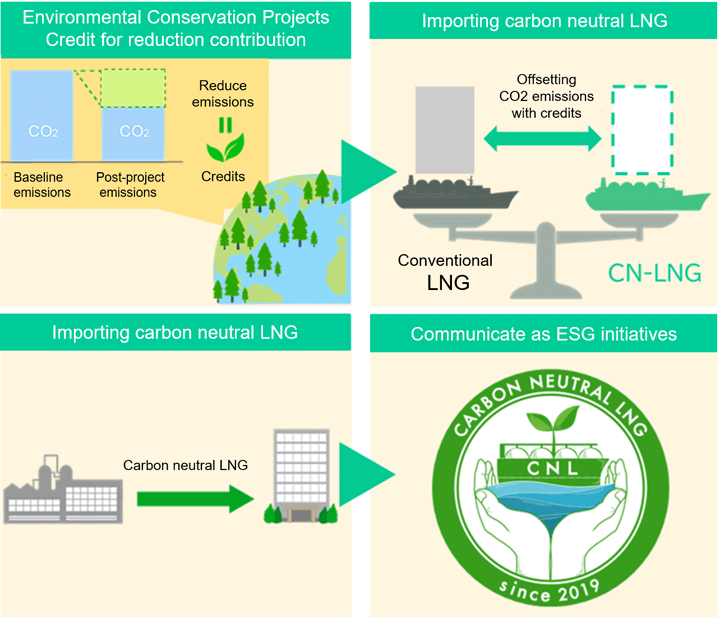

Introducing carbon-neutral LNG (CNL)

CNL is an LNG (Liquid Natural Gas) that allows CO2 credits to offset (carbon offset) greenhouse gases generated through the entire process from natural gas mining to combustion, and is thought to not increase CO2 on a global scale even when burned.

Starting in April 2021, we converted the gas used at Duskin Tokyo Tama Central Plant to carbon neutral gas, and are curbing CO2 emissions. An annual CO2 emission reduction of approximately 70% is expected at the Plant.

Moving forward, in addition to promoting considerations into introducing CNL usage in other plants as well, in our journey towards the actualization of a sustainable society we also aim for the expansion and normalization of CNL usage and the increasing of CNL usage value through the efforts of the CNL procuring and supplying Tokyo Gas Co., Ltd. and the "CNL Buyers Alliance" composed of Duskin and 14 other CNL purchasing companies.

Eco-Driving (CO2 reduction in product delivery)

At Duskin, using business vehicles to deliver products and services is an absolute necessity. All drivers practicing Eco-Driving (idling stops, restricting sudden starts and stops, and preventing excessive speeds) contribute to CO2 emission reduction.

At production and logistics facilities, we enforce energy-conserving driving through registration with Logicompass (vehicle operation management system). We also strive for the normalization of Eco-Driving through efforts including holding learning sessions in each region. Moreover, we review our delivery routes to improve transporting efficiency and reduce CO2 emissions.

| FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |

|---|---|---|---|---|---|

| Vehicles with Logicompass (quantity) | 320 vehicles | 320 vehicles | 320 vehicles | 320 vehicles | 320 vehicles |

Promoting usage of low-emission vehicles

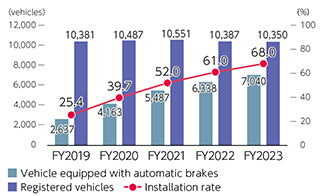

At Duskin, we promote the usage of low-emission vehicles. Our policy calls for low-emission cars to be used as business vehicles and even more environmentally friendly vehicles such as hybrid cars to be used at our headquarters.

We are changing out our headquarters vehicles for vehicles that meet the latest emissions control standards, such as hybrid and electric automobiles. Furthermore, to actualize idling stops and rear-end collision prevention, we actively promote the usage of business vehicles equipped with automatic braking mainly at our company-owned sales locations and affiliated companies.

Low-emission vehicle

Certified low-emission vehicles with automatic brakes

Practical tests for converting Duskin's sales vehicles to EVs

Following practical tests on electric vehicle (EV) adoption, which assessed environmental impact reduction, operational costs, practicality and other factors, we plan to shift to EVs as part of our commitment to achieving a decarbonized society.

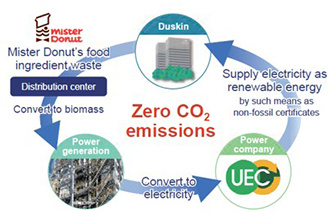

Turning food ingredient waste into energy

A total of five Duskin locations, including our head office building and its surrounding facilities are now using 100% certified renewable energy powered by biomass generated from food ingredient waste from our distribution centers and other companies in the Mister Donut business. This way, we ensure efficient use of limited resources, establishing a recycling loop to minimize waste.

CO2 emission reductions at Food Group shops

At Mister Donut and Food Group shops, we strive for CO2 emission reductions while also maintaining a pleasant atmosphere for customers.

We strive to actualize a progressively successful environment of energy conservation and decreased environmental burden by reassessing air conditioning temperature settings and necessary lighting areas and reassessing daily shop operations, including concentrated turning off of back area lights and utilities meter management.

In addition to making energy conservation a standard condition for freezing and refrigeration equipment installed in shops, we standardized LED lighting usage in newly opened shops and promote installing LED lighting at existing shops as well during remodeling, etc.

| FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |

|---|---|---|---|---|---|

| Shops with LED (shops) | 735 | 814 | 911 | 1,020 | 1,025 |

| Installment rate (%) | 76.7 | 83.1 | 91.4 | 95.2 | 97.8 |

Furthermore, we conduct equipment cleaning and maintenance periodically. And in addition to maintaining optimal equipment capability, we also introduced energy management in FY 2015 in our mission to actualize further reduction of energy usage.

As a result of these kinds of efforts, the monthly shop electricity usage amount has been gradually dropping. We will continue to normalize and standardize these environmental efforts.

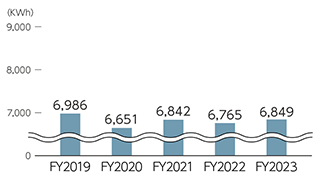

Monthly electricity use per Mister Donut shop

-

External LED sign

Interior LED lighting