It is a top of the page.

- Home

- Sustainability

- Society

- Food Safety and Reliability

Food Safety and Reliability

Basic Policy

At Duskin, we prioritize food safety above all else. To prevent any negative impact on our customers, we establish quality standards for all food products—from development and provision to the moment they are enjoyed—ensuring safety and delivering peace of mind.

Food Safety Council

All product development and specification changes undergo safety checks by the Food Safety Council, which includes third-party participants such as the manager responsible for food product safety and representatives from the product development and quality assurance divisions.

Based on legal regulations and our own company standards, we verify every aspect of food safety: the raw materials and their origins, compliance of additives, allergy information, validity of foreign matter removal processes, management of pesticide and antibiotic residues, storage inspection results for products and ingredients, management status of manufacturing subcontractors and logistics/storage service providers, and handling procedures at sales locations—ensuring safety at every stage.

Going forward, our top priority will be to ensure that raw materials and products are used exactly as specified, while also providing support so that developers can deepen their overall understanding of safety.

Audit of Logistics and Storage Service Providers

To maintain the quality of our products and raw materials, we conduct audits during the initial phase of our business relationship with new partners. This includes a comprehensive 300-item inspection covering storage conditions, temperature control, shelf-life management, and other operational practices at logistics centers responsible for storing raw materials and delivering them to sales locations.

In addition, the Purchasing & Logistics staff of the Mister Donut Business Group conduct periodic inspections.

Hygiene Management at Sales Locations

At our food service shops, including Mister Donut, we maintain rigorous hygiene standards on a daily basis. For example, when employees enter the shop, their overall health and cleanliness, including the hygiene of their fingertips, are thoroughly checked. In addition, hygiene management checkpoints are incorporated into each stage of the work process to ensure strict hygiene control.

Also, we have an external inspection body perform periodic spot hygiene inspections without prior notification four times per year. In addition to conducting inspections with over 100 items checking hygiene management status and bacteriological inspections of donuts and drinks via samples, we also strive to strengthen the prevention of contamination from bringing items into the shop. We maintain comprehensive hygiene management conditions by receiving evaluations and guidance for improvement from the specialist viewpoint of external inspection bodies.

Implementation of Hygiene Management Based on HACCP Principles

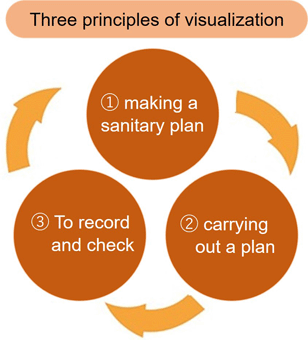

Our hygiene management practices, which incorporate HACCP* principles, are built on the idea of "visualizing" safety by rigorously implementing and documenting all pre-planned hygiene control measures designed to prevent foodborne illness, foreign-object contamination, and other risks. By keeping accurate records of each action taken, we are able to identify early warning signs before issues arise, prompting timely maintenance or corrective improvements. This proactive approach ultimately helps prevent major food safety incidents.

- * HACCP stands for Hazard Analysis and Critical Control Point. It is a hygiene control method designed to ensure product safety by identifying potential hazards—such as contamination by foodborne pathogens or foreign objects—beforehand, and by managing the critical points in the production process that help reduce these risks. This management applies to every stage, from the receipt of raw materials to processing, storage, and final shipment (or service).

Providing Information on Food Safety and Reliability

Providing nutritional information (enhancing access to better nutritional information)

At Mister Donut, we disclose nutritional information—such as calories, protein, fat, carbohydrates, and salt-equivalent content—in accordance with the established labeling standards. This information is updated regularly to reflect the launch of new products or improvements made to existing products.

In our shops, our staff can print out the nutritional information and provide it to customers upon request. Nutritional information for each product is also available on the official Mister Donut website.

In addition, the calories per item are shown on the price cards.

Providing allergen information

As food allergies continue to be a growing public concern, Mister Donut is committed to making allergen information easily accessible to as many customers as possible. In our shops, price cards indicate whether products contain any of the specified allergens. For ingredients classified as "allergens comparable to the specified ones," our staff can provide a printed list upon request.

Allergen information for each product is also available on the official Mister Donut website.

Mister Donut nutritional information and allergy information (www.misterdonut.jp)

- Note: The English version is at the bottom of the linked page.

Information on the origin of primary ingredients

- For any inquiries about the origin of primary ingredients of Mister Donut products, please contact:

- Mister Donut Customer Center

- Telephone: 0120-112-020 (only available in Japan)

- Office Hours: 9:00 am – 5:00 pm (closed on Sundays)

Preventing Unwanted Secondhand Smoke

In the Mister Donut business operated by the Food Group, we have implemented various measures at each shop, such as full-day no-smoking policies, time-specific no-smoking periods, and designated smoking areas, to prevent unwanted secondhand smoke.

Meanwhile, the revised Health Promotion Act, which was fully enforced in April 2020, requires even stronger measures to prevent unwanted secondhand smoke. In response, shops that had previously offered smoking-designated seating or ventilated smoking sections have now adopted one of two measures: either becoming completely smoke-free or installing smoking booths where no seating is provided and eating or drinking is not allowed.

Looking ahead, we aim to create shops that provide a safer and more comfortable environment for all customers, including families with children, while also prioritizing the health of the employees who work there.

Participation in Industry Initiatives

As a member company of the Japan Foodservice Association*, the industry organization that oversees Japan's foodservice sector, we participate in various committees and contribute to activities such as policy proposals related to the foodservice industry and market trend surveys. We also refer to and strive to comply with the guidelines established by the Association.

- * The Japan Foodservice Association (commonly known as JF) was established in 1974 with the approval of the Ministry of Agriculture, Forestry and Fisheries to contribute to the development of Japan's foodservice industry and the creation of a rich food culture. With approximately 800 member companies, including both regular and supporting members, the Association is the largest organization related to the foodservice industry in Japan.

Case study

Early adoption of low trans fat oil

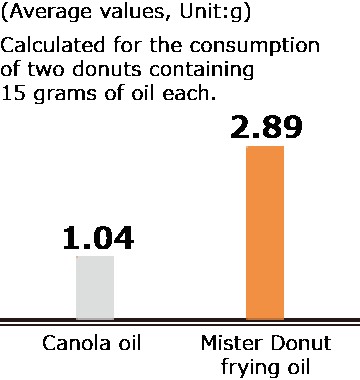

Consuming large amounts of trans fat is said to increase the risk of coronary heart diseases due to a higher bloodstream concentration of LDL cholesterol (low-density lipoprotein, or "bad" cholesterol) and a lower bloodstream concentration of HDL cholesterol (high-density lipoprotein, or "good" cholesterol). *1 The average trans fat intake quantity in Japan is lower than in other countries, and no specific standards have been established. *2 However, Mister Donut dove into the issue of trans fat from an early stage, and in December of 2007 started using frying oil with significantly lowered trans fat amounts at all shops.

As a method of reducing trans fat, we have continued research and development not only on frying oils but also on raw materials such as mix powders and coating ingredients. As a result, we have kept the trans fat contained in all our donuts and pies to an average of approximately 0.25 g*3. In our research and development efforts, we remain committed to preserving the taste, texture, and aroma of Mister Donut products that our customers have loved over the years.

- *1: The disease risk is based on the 2003 report of a joint expert meeting from the World Health Organization (WHO) and the Food and Agriculture Organization of the United Nations (FAO).

- *2: In Japan, according to data announced in 2007 (estimated from the amount produced), trans fat intake quantity is an average of 1.32 g per day and the percentage of trans fat to total intake energy is approximately 0.6%, which clears the WHO and FAO recommendation of "less than 1% of total intake energy."

- *3: The figure of approximately 0.25 g represents the average value of all items offered as of April 1, 2023 (based on our company research). The numbers are calculated values derived from ingredient formulations. Because each item is handmade in our shops, slight variations may occur.