It is a top of the page.

- Home

- Sustainability

- Society

- Sustainable Supply Chain

Sustainable Supply Chain

Basic Policy

In order to make sure our transactions with supplier companies are based on mutual understanding and trust, we open our doors to companies across a wide spectrum both in Japan and abroad. And in addition to maintaining principles including faith, fairness, equity, and equal opportunity, our procurement activities comply with the law and social norms.

To actualize these goals, we have set as follows the philosophies in our conduct guide, the "Duskin Code of Conduct".

●Duskin Code of Conduct 4: With respect to our suppliers

- 1. Legal compliance in transactions

- We will fully understand and comply with relevant laws and regulations, and also ensure fairness in all transactions in order to maintain trusting relationships with our business partners. We will also request our business partners to ensure compliance.

- 2. Ensuring the safety of products and services

- We will constantly share and verify information pertaining to quality and safety with our business partners in order to provide safe and reliable products and services to consumers and customers.

- 3. Equal relationships with business partners

- We will engage in thorough discussions with all business partners on an equal footing and strive to build sustainable, mutually beneficial relationships across the entire supply chain.

- 4. Selection of, and ongoing engagement with, responsible suppliers

- When selecting business partners and continuing to do business with them, we will follow proper procedures by considering not only price, quality and delivery time, but also aspects of the entire supply chain, including efforts to address business and human rights (such as human rights protection, labor practices and child labor) and environmental conservation.

- 5. Maintaining business relationships within reasonable limits

- We will build relationships of trust with our business partners by deepening communication in our operations. We will not accept, offer or solicit entertainment, hospitality or gifts beyond the bounds of social norms*, including instances involving our families.

- *The bounds of social norms refer to instances that do not influence business decisions.

| FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |

|---|---|---|---|---|---|

| Number of suppliers | 448 companies | 449 companies | 454 companies | 454 companies | 475 companies |

| Amount spent | 48,004 million yen | 50,105 million yen | 57,337 million yen | 62,882 million yen | 64,249 million yen |

Maintaining quality and considering the environment

When starting transactions with a supplier, we set requisite conditions including the agreement with Duskin management philosophy, possession of a management creed, maintaining a quality control and assurance system, compliance with laws for issues such as the environment, waste, recycling, labor practices, and labor safety hygiene, and active involvement in environmental and societal issues.

Strengthening partnerships with suppliers

In order to strengthen partnerships with our supplier companies, we believe it is important for them to understand the Duskin way of thinking. As part of this endeavor, Duskin holds a Supplier Study Session every year to share information on quality policies, compliance-related actions, and business plans for that fiscal year (development, sales promotion, and purchasing / distribution plans).

Additionally, we also receive information as needed from supplier companies regarding issues including industry trends, and market trends, as well as environmental and societal issues from an ESG and SDGs perspective.

| Participating company | FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 |

|---|---|---|---|---|---|

| Direct Selling Group (number of companies) |

169 companies | 196 companies | 203 companies | 198 companies | 188 companies |

| Mister Donut Business Headquarters (number of companies) |

Voluntarily suspended due to COVID-19 pandemic |

75 companies | 71 companies | 88 companies | |

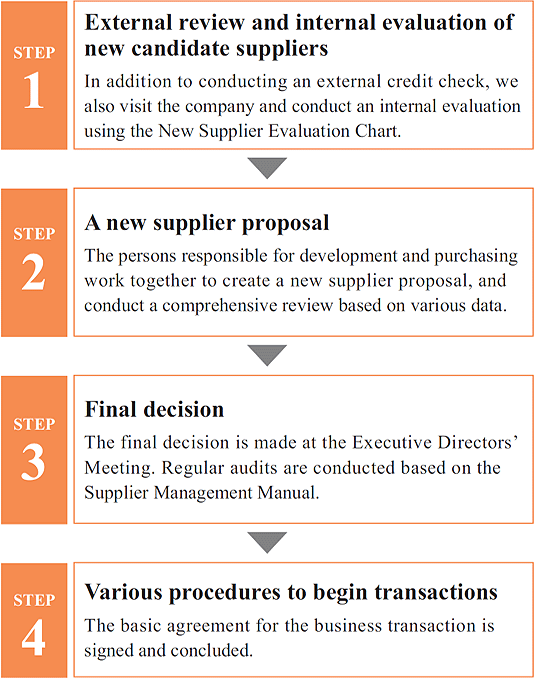

Selecting new suppliers

When selecting new suppliers, we always select companies that have completed prescribed procedures in accordance with regulations, with the prerequisite of fair, equitable, and free competition.

We ask new supplier candidates to prepare a self-assessment in advance to increase transparency and acceptability. Simultaneously, in addition to conducting external credit checks, Duskin representatives visit the candidate companies and perform an internal evaluation based on our own independent "Supplier Evaluation Chart".

This "Supplier Evaluation Chart" also checks candidate companies' ISO certification status, waste management status, efforts to reduce energy use, human rights, labor practices, and work environment.

Also, after transactions begin, we conduct regular audits based on the "Supplier Management Manual" to ensure quality and a stable supply of products, and we also work to reduce management risk by doing business with multiple companies for major commercial products.

Precautionary measures for product supply in emergencies

If a Duskin product manufacturer suffers damage from a natural disaster or other causes and product supply temporarily stops, this will cause inconvenience to the customer as well. Therein, we take proactive measures for the core products of the Dust Control Business and the Food Business, which are particularly influential.

- ■ Proactive measure philosophy

- 1.With the exception of procuring products that depend on a specific company from the viewpoint of manufacturing technology specificity, etc., we handle procurement by purchasing from multiple companies.

- 2.We survey the implementation status of proactive measures at our direct suppliers.

- 3.We preemptively select similar and substitute products that can be substituted in emergencies.

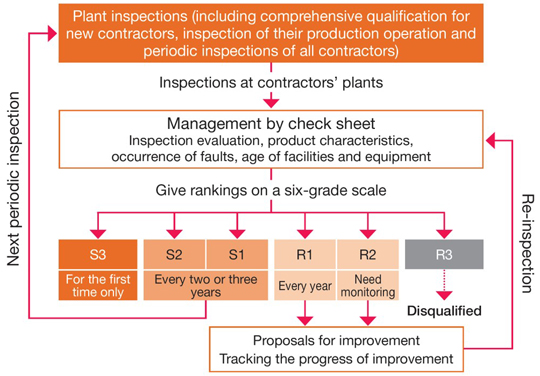

Periodic audits of outsourced raw material manufacturing plants

raw material manufacturing

plant (storehouse)

For plants of food product manufacturing subcontractors, we implement an initial audit before new transactions, audits at the time of manufacturing, and periodic audits in our quest for constant improvement. In our audits, food product plant specialist representatives evaluate the plant based on checkpoints that cover a wide range of areas, including plant facility and process management and sanitation and production management. Furthermore, periodic audits are conducted by ranking each plant according to audit evaluation points, etc., and are conducted according to rank.

| FY 2020 | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |

|---|---|---|---|---|---|

| New audits | 3 plants | 11 plants | 6 plants | 0 plants | 0 plants |

| (New foreign plants) | No audits | No audits | No audits | No audits | No audits |

| Periodic audits | 24 plants | 18 plants | 36 plants | 35 plants | 28 plants |

Basic Policy Concerning Sustainable Procurement

In addition to complying with the Duskin Code of Conduct (Compliance), we also work together with our suppliers to promote procurement activities that fulfill social responsibilities in areas including human rights, labor, and global environment conservation, and contribute to the actualization of a sustainable society.

- 1.Legal compliance and respect for international norms

- We promote fair and equitable procurement activities that comply with the laws of each nation and region and respect international conduct norms.

- 2.Consideration for human rights, labor, and safety and sanitation

- We promote procurement activities that consider the labor environment, safety, and sanitation in accordance with the "Basic Policy Concerning Respect for Human Rights" (initiatives promoting respect for basic labor rights such as the freedom of association, the right for workers to organize, and the right of collective bargaining, the prevention of forced labor and child labor, elimination of discrimination, and the promotion of comfortable work environments and human rights education and awareness).

- 3.Ensuring quality and safety

- We promote procurement activities in accordance with the "Duskin Quality Policy" that aim for the assurance of high quality, safety, and security based on the optimal standards of quality, cost, and supply.

- 4.Consideration for the global environment

- We promote procurement activities that consider global environmental conservation in accordance with the "Duskin Environmental Policy" (climate change measures including waste reduction, effective resource use, CO2 emission reduction, conservation of water resources and biodiversity, and continual improvement through environment management systems).

- 5.Maintaining information security

- We promote procurement activities that strictly manage confidential and private information.

| FY 2024 | |

|---|---|

| Human rights, labor problems, etc. | No instances where serious human rights violations or noncompliance were found. (0 instances in FY 2021, 0 instances in FY 2022, 0 instances in FY 2023, and 0 instances in FY 2024) |

| Notification and consultation desk for supplier companies | 0 usages of "Duskin Purchasing Clean Line" |

| Number of independent contractor deaths related to work | No instances. (0 instances in FY 2021, 0 instances in FY 2022, 0 instances in FY 2023, and 0 instances in FY 2024) |

Supplier audits regarding environmental and societal issues

Concerning palm oil extracted from the palm tree fruit, there is worldwide concern that the development of agricultural land for the trees will have a negative impact, including the destruction of tropical rainforests. So, when using these kinds of raw materials, we work together with supplier companies that we share partnerships with to construct appropriate procurement systems.

Together with trading companies and manufacturers, we regularly conduct onsite inspections of the Johor, Malaysia palm tree orchard and palm oil extraction plant and perform periodic audits of local oil manufacturing plant facilities.

In addition to attaining certification for the three international standards of the ISO9001 quality management system, ISO22000 food safety management system, and ISO14001 environment management system, this plant has also attained certification by HACCP, an international standard for food product hygiene management systems. Additionally, we implement thorough hygiene management by conducting Five S (Sort, Set in order, Shine, Standardize, and Sustain) activities and safety and hygiene training sessions monthly. Furthermore, regarding plant wastewater, we consider the surrounding environment through initiatives including self-inspections based on criteria we have set that are stricter than governmental standards and inspection-related data saving.

Palm oil must be pressed within 24 hours of harvesting the palms on the orchard or the quality will deteriorate. Because of this, extraction plant facilities for donut oil suppliers of Mister Donut are located within 48 kilometers of an orchard. The orchard and extraction plant facilities also implement 5S activity initiatives. In addition, sewage discharged from orchards and extraction plant facilities is treated by microorganisms in settling ponds, and the gases produced during the process are accumulated in an onsite plant to be reused as fuel.

Periodic oil manufacturing plant audit

Palm tree orchard